Pneumatic pipes are a type of PPR piping system used in industrial and air settings. Transporting compressed air or other gases between locations involves the use of pneumatic pipes. Metal, plastic, or composite materials are frequently used in their construction. Most typically, polyethylene tubing, hose systems, and tube systems are used in pneumatic pipe systems.

Production facilities for vehicles, businesses, and other industrial settings where gas or air is needed to run machinery usually use pneumatic pipes. Pneumatic pipes are available in a selection of sizes and forms to meet the unique requirements of each application. Depending on their intended usage, they can be rigid or flexible, easily adjustable, or specially designed to fit any situation.

Compression-style fittings: Compression-style fittings on the pipes provide a tight, leak-free connection and ensure the integrity of the fire suppression system.

Corrosion-free Material: All fittings are composed of corrosion-free material, which will not rust or deteriorate, hence extending the durability and longevity of the pipes.

Smooth Inner Surface: The inner surfaces of the pipes are smooth, which reduces the operational pressures needed by the motor and pump.

High Chemical Resistance: The pipes are appropriate for use in areas where there is a high risk of chemical exposure due to their high chemical resistance. Additionally, they stop moss and germs from growing inside the pipes.

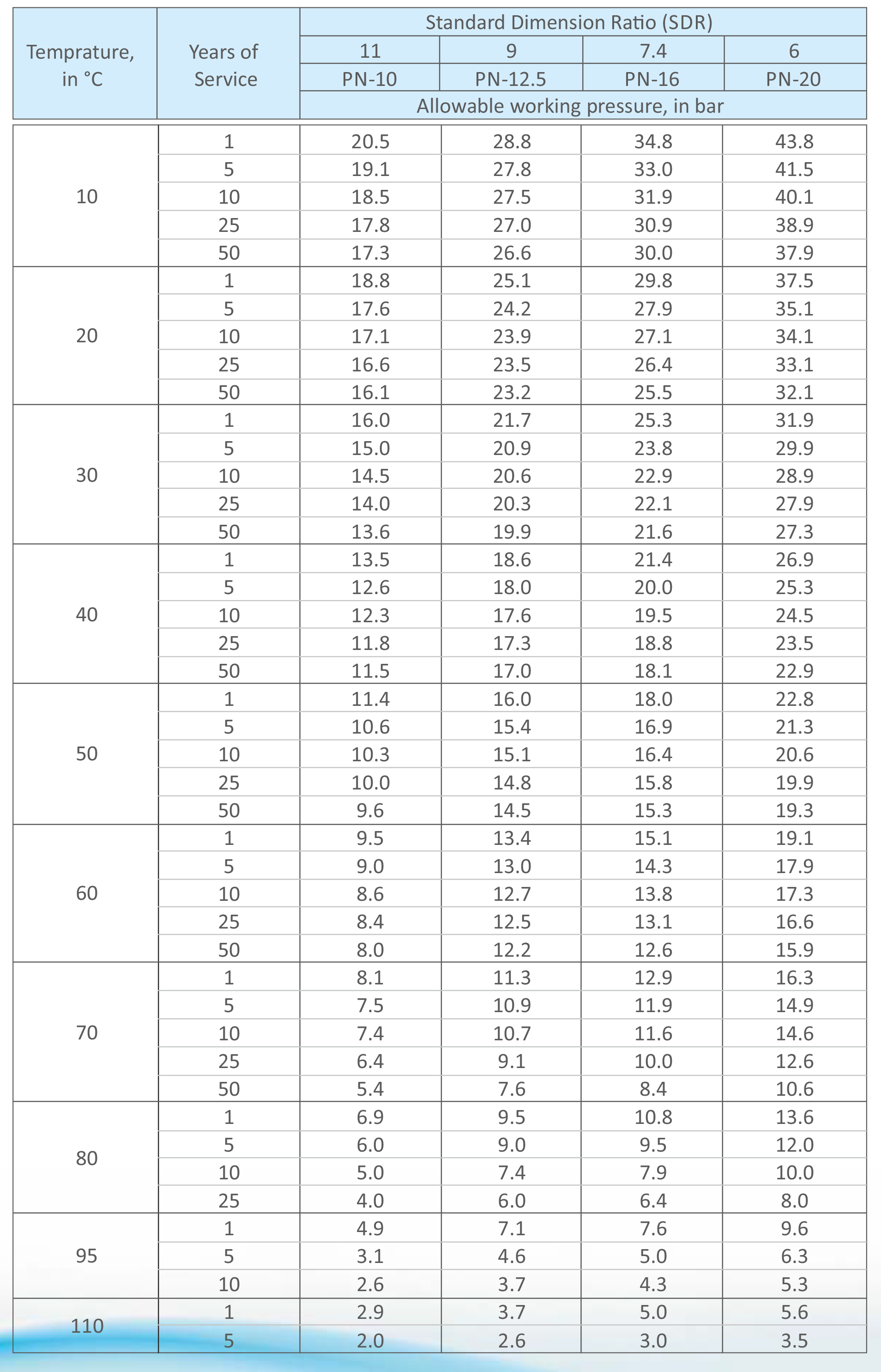

High-Temperature Resistance: The pipes can withstand high temperatures (up to 110°C) without compromising their structural integrity.

Properties: The pipes keep their shape and integrity even in harsh situations since they don't crumble and don't distort.

Non-contracting diameters: Because the pipes' diameters are non-contracting, they won't contract or enlarge with time.

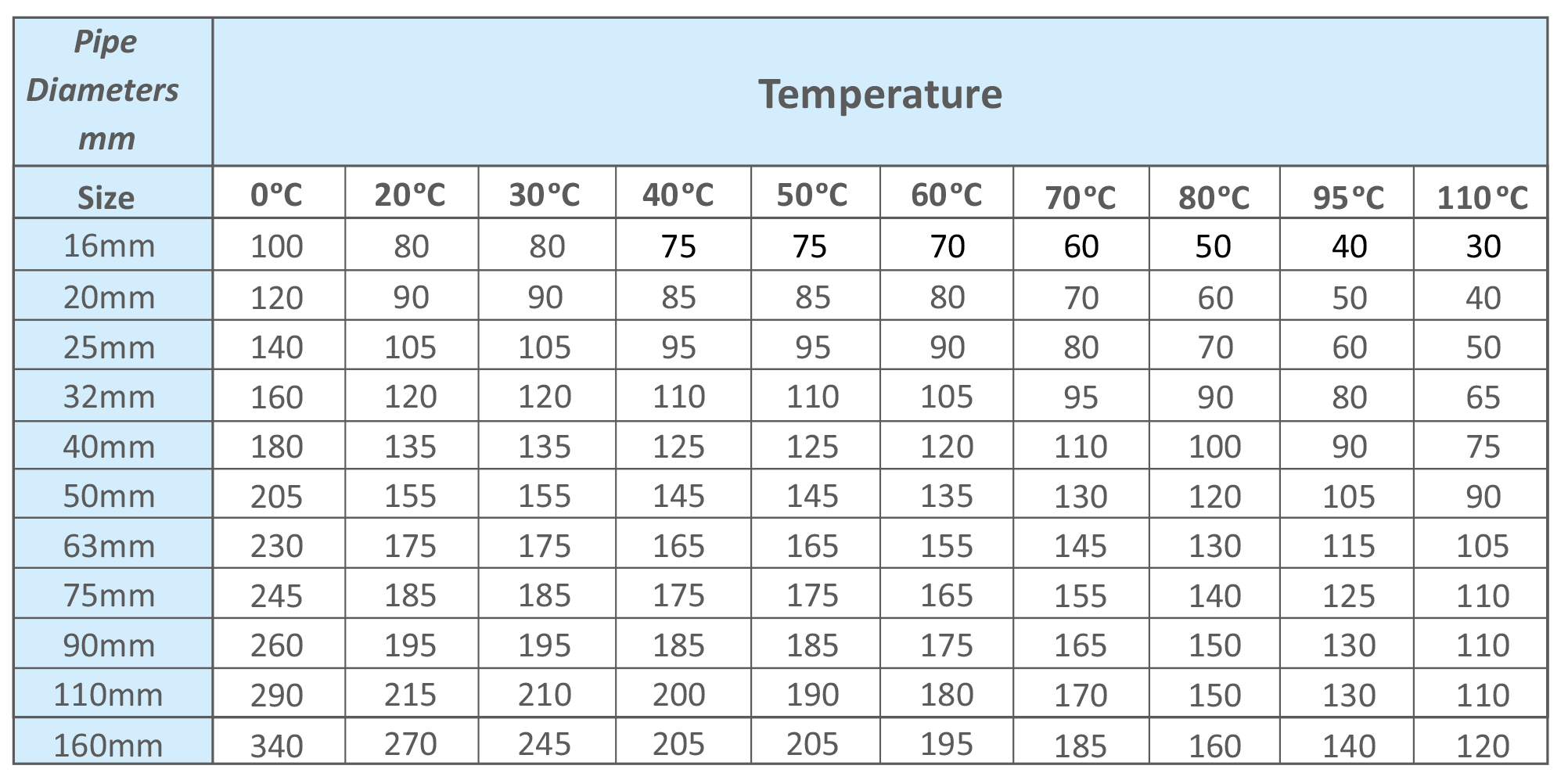

Variety of Size Options: The pipes are offered in a wide range of sizes, from 16mm to 355mm, to serve a variety of needs.

Fusion Joints: No external adhesives are utilized in K.P.T Pneumato piping joints, which are fusion joints. As a result, after fusion welding, pipes and fittings become homogenous materials with unbreakable joints.

Simple Fusion Welding Technique: The fusion welding technique utilized in the pipes is quite simple and is easily learnable. K.P.T. will give clients training and the bare minimum in extra parts to handle any emergency.

Applications of Pneumatic Pipes:

Compressed air systems: In industrial contexts, pneumatic pipes are frequently used to deliver compressed air. Tools and equipment like air hammers, drills, and spray guns are all powered by compressed air.

Vacuum Systems: Pneumatic pipes may also be utilised to build vacuum systems, which are applied to a number of tasks, including packing and material handling.

Conveying Systems: In a number of sectors, including food processing, pharmaceuticals, and mining, powders, granules, and other tiny particles can be transported using pneumatic pipes.

Control Systems: Pneumatic pipes are utilised in a number of industrial applications to regulate the flow of fluids and gases.

Medicinal Applications: Medical gases like oxygen and nitrous oxide may be transported via pneumatic pipes in hospitals and other healthcare facilities.

Environmental Control: Air, gas, or liquids utilized to regulate the environment are transported through pneumatic pipes.

Glass fibre-reinforced polypropylene (GFRPP) pipes provide the following benefits:

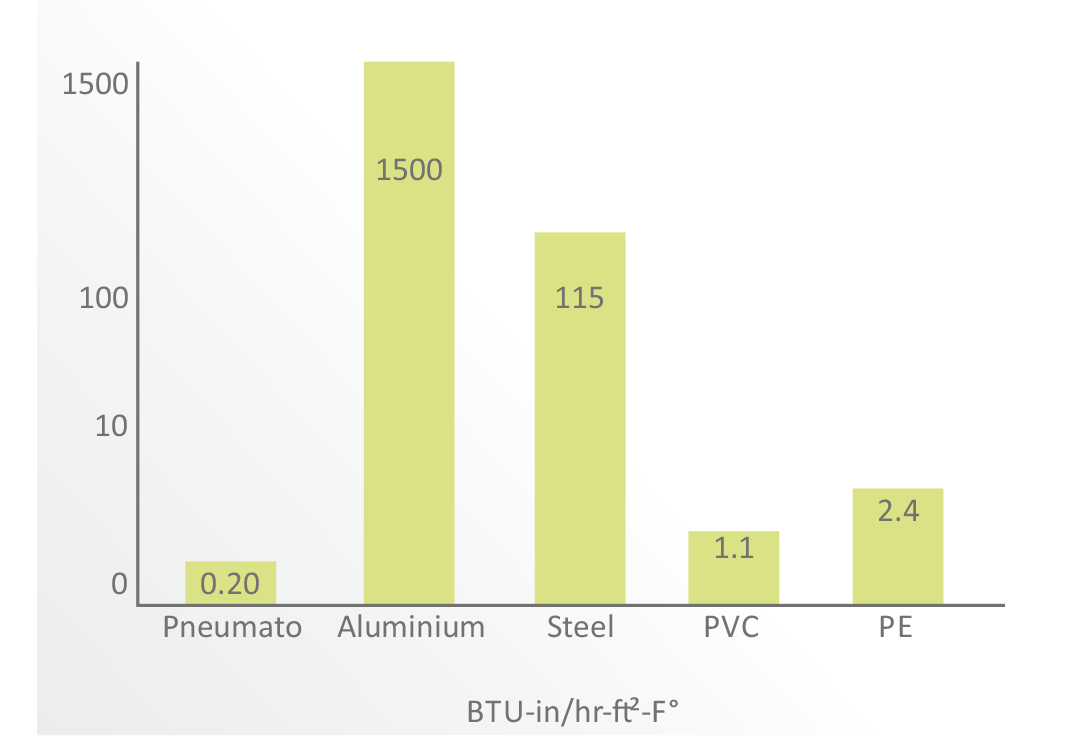

Low Heat Loss: GFRPP pipes lose less heat because of their lower thermal conductivity.

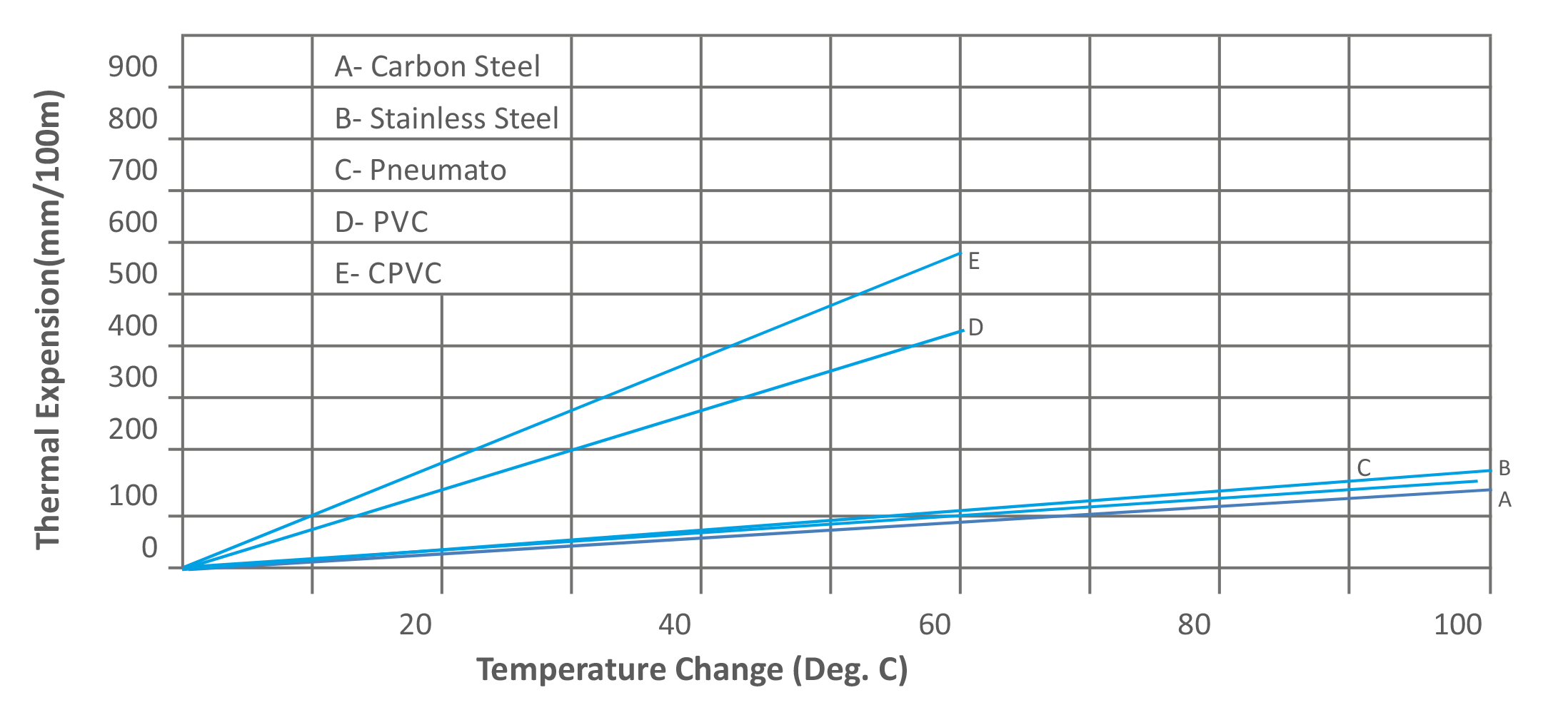

Reduced Sagging: GFRPP pipes droop less because of their low thermal expansion, resulting in a steady and reliable performance.

High Temperature and Pressure Resistance: GFRPP pipes are extremely resistant to high temperatures and pressures. Thanks to the built-in glass fibre reinforcing layer.

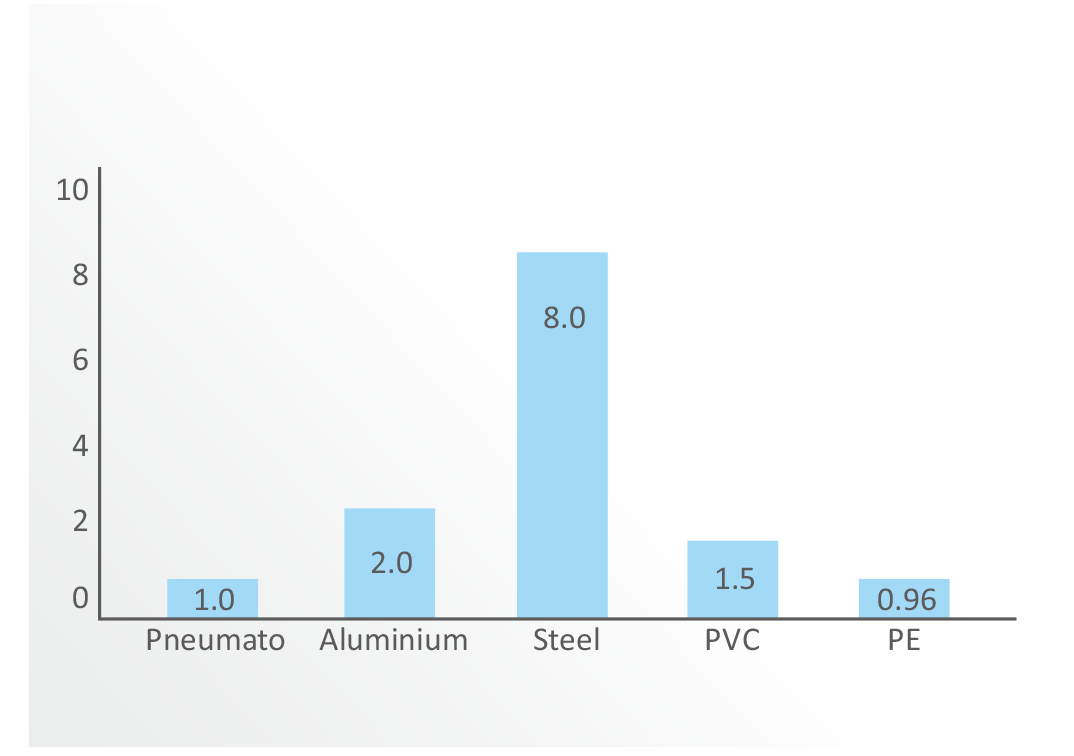

Low Friction: Compared to other pipes, GFRPP pipes offer a 40–60% lower friction rate thanks to their mirror-finished inner surface and RA value of 0.1 microns.

Reduced Clamping: GFRPP pipes are more effective and simple to install since they experience less clamping due to their low thermal expansion.

Leak-Free Fittings: The style fittings that come with GFRPP pipes provide a tight, leak-free fit.

Zero Leakage: Socket fusion joints are used to unite GFRPP pipes, and this ensures that there will be no leaks.

High-Glass Fiber Reinforcement: GFRPP pipes include a 60% glass fibre-reinforced layer, guaranteeing high performance and long-lasting durability.

Low Linear Expansion Coefficient: GFRPP pipes may be used in direct sunlight because of their UV resistance on the upper layer.

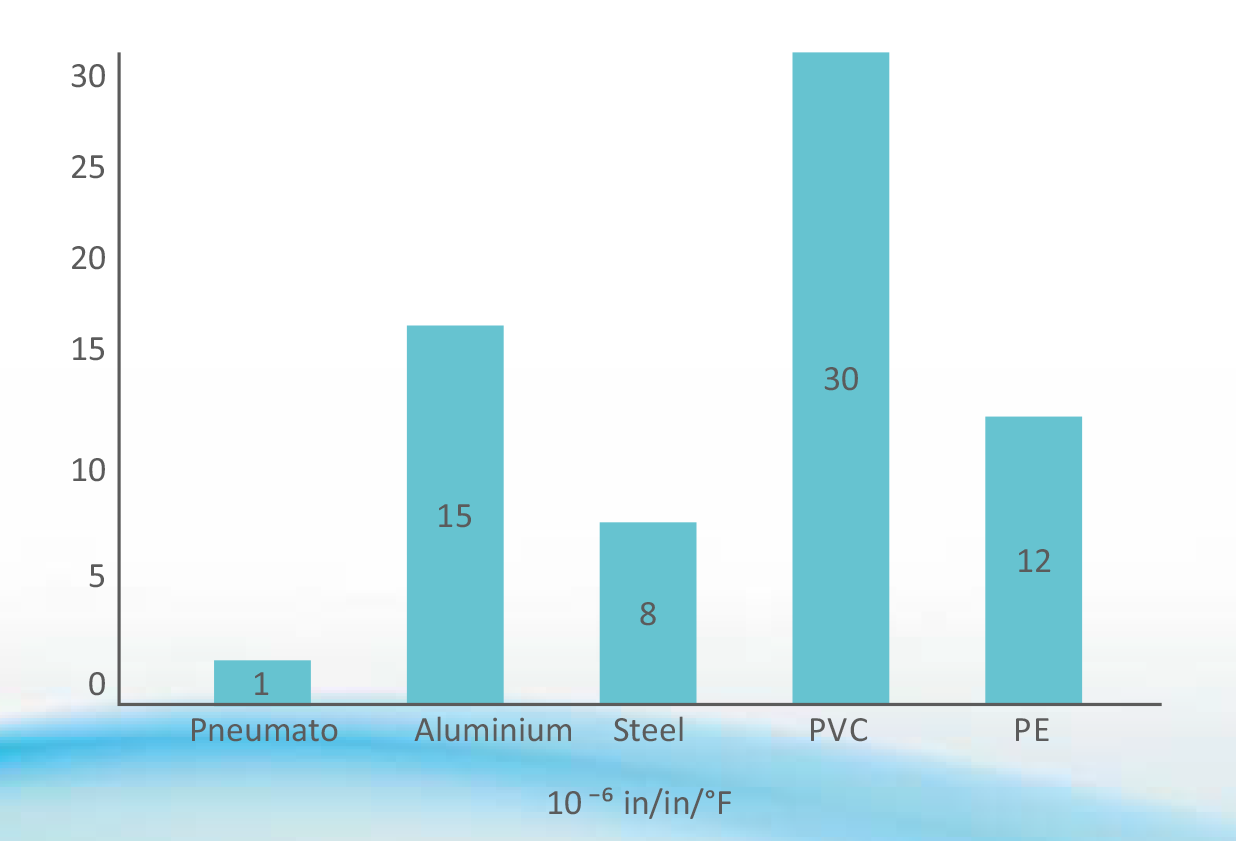

Low Linear Expansion Coefficient: Compared to standard PPR Pipes, the linear expansion coefficient of GFRPP pipes is just one-third as high.

K.P.T. Pneumato pipes are specifically made to build primary and secondary networks for vacuum, neutral gases, and compressed air. K.P.T. Pneumato Pipes can handle high operating pressure because the FRP also stops oxygen and other gases from entering the pipe. For the provision of compressed air, gas, and oxygen, K.P.T. Pneumato pipes are a trustworthy and safe option.

© 2025-26 KPT Piping System. All Right Reserved. | Privacy Policy