KPT-PPR Plumbing Pipe system is made from Basel & Hyosung materials, considered one of the best PPR-C materials worldwide, a Random Copolymer Polypropylene (PPR-C) approved for the production of pipes and fittings according to DIN 8078 & DIN 16962 standards. Reliance PPR Raw material is a thermoplastic resin that is transformed into the finished product by a rise in temperature, which plasticizes the material, allowing the pipe to be produced by means of EXTRUSION and the fittings by MOULDING. The raw material is supplied in granules precolored.

Special heat resistance is one of the features of this material. Its physical and chemical properties are well suited to the transfer of potable water and the heating sector. Depending on the pressure, it is possible to use KPT – pipes for constant temperatures up to 700 C with a service life of more than 50 years. Peak temperatures of 1000C arising from short disruptions are not creating any problems.

KPT pipes and fittings are made from polypropylene random co polymer specially developed for this use. Its characteristics make it suitable for both Industrial and Commercial applications, with outstanding reliability over time.

One special feature of the KPT PPR-C pipe system is the assembly technique, in which the parts to be connected are welded by melting and fusion. After fusion welding, the pipe and fittings form a single continuous body with none of the problems which may derive from potential leakage points. It makes the joints PERMANENT. No sealants or adhesives are required for these permanent connections.

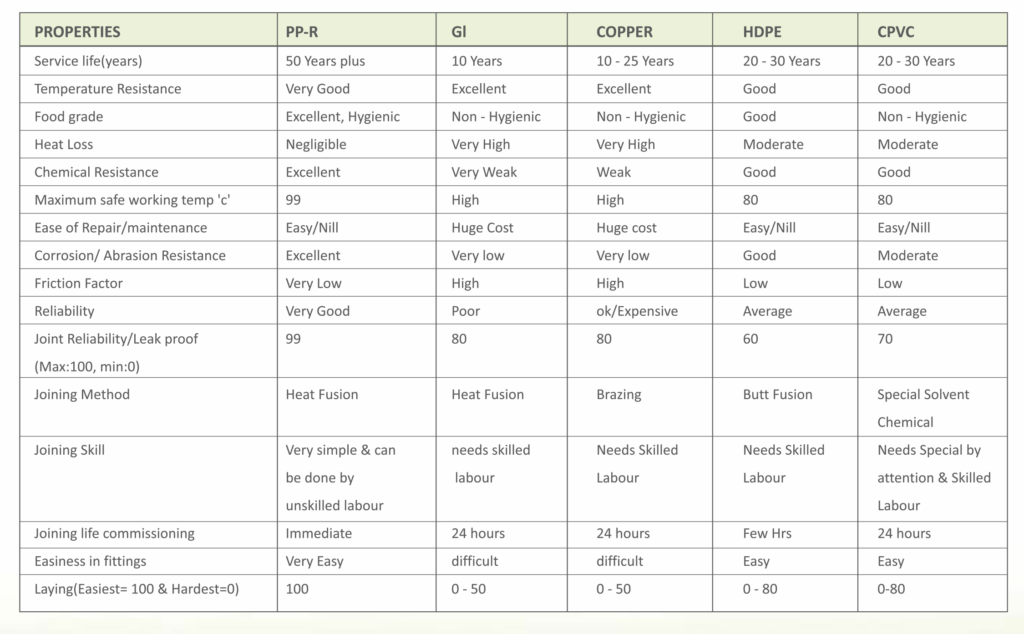

Polypropylene has high resistance to a large number of aggressive substances and is, therefore, particularly suitable for special applications. The table below provides the resistance of Polypropylene to various chemicals. For the transport of combustible fluids, please comply with any legal regulations in force. Take care when the installation is to carry water with chlorine content over the limits permitted by law and/or contains elements that induce oxidation in general.

Made from the finest Hyosung material per the standards of DIN 8078 & DIN 16962, these PPR pipes are manufactured from such a raw material that transforms the final product with the influx of temperature in order to plasticize the material, creating pipes through Extrusion and fittings through Moulding.

Shouldering the reputation of the excellent PPR pipe manufacturers in India, our pipes can endure heat, and their physical and chemical properties ensure that they can carry potable water and that too in the heating sector. These fabulous features make it possible to use pipes for a constant temperature of 700 C, offering a service of 50 years.

© 2025-26 KPT Piping System. All Right Reserved. | Privacy Policy